Returnable glass packaging has long been considered a sustainable alternative in the brewing industry, both for reducing environmental impact by lowering waste generation and for its positive influence on the total product cost. Reusing the same bottles allows cost amortization throughout their lifecycle. However, for this economic advantage to be realized, each bottle must be reused on average 10 to 20 times before being discarded, according to industry studies. Achieving this number depends directly on the practices adopted during the washing process.

The service life of a bottle is directly linked to the efficiency of the washing process. The bottle washer is the equipment responsible for creating ideal conditions for cleaning agents to act, both in removing labels and in eliminating internal and external impurities. After washing, bottles go through electronic inspection systems that detect cleaning failures and structural damage (such as cracks, chips, or imperfections), rejecting those that pose risks to consumer safety.

When these steps are poorly executed, an excessive number of bottles are returned to the washing process, reducing packaging lifespan and increasing operational costs.

The foundation of the cleaning process lies in Sinner’s Circle, which defines four essential factors: time, temperature, mechanical action, and chemical agent. In industrial environments, bottle washers deliver these four elements through immersion tanks and agitation systems.

The process begins with pre-rinsing, followed by cleaning tanks (typically two to four), where bottles are immersed in alkaline solutions, usually with 1.5% to 3.0% NaOH concentrations, heated between 60°C and 80°C. At this stage, label removal also takes place, aided by pumps that circulate the solution and suspend residues, which are then collected by conveyors.

The key cleaning factors in this stage are:

- Chemical agent: proper concentration of the alkaline solution (NaOH)

- Temperature: between 70°C and 80°C, optimizing soil removal

- Contact time: sufficient immersion for chemical action

- Mechanical action: agitation promoted by label extractor pumps

The concentration of the solution must be constantly monitored, including sodium carbonate (Na2CO3) levels, as it impacts both pH and the detergent power of the solution. High temperatures also favor carbonate formation and precipitation of insoluble salts (such as calcium and magnesium), which can impair washing performance.

To enhance cleaning efficiency and reduce caustic soda consumption, it is recommended to add sequestering agents and surfactants to the solution. This practice improves detergent penetration into residues, reduces foaming, facilitates rinsing, and contributes to extending bottle lifespan.

Contact time with the chemical agent is critical to completing the washing process. Adequate time is required for residues to be penetrated and for adhesives to react, ensuring complete label removal.

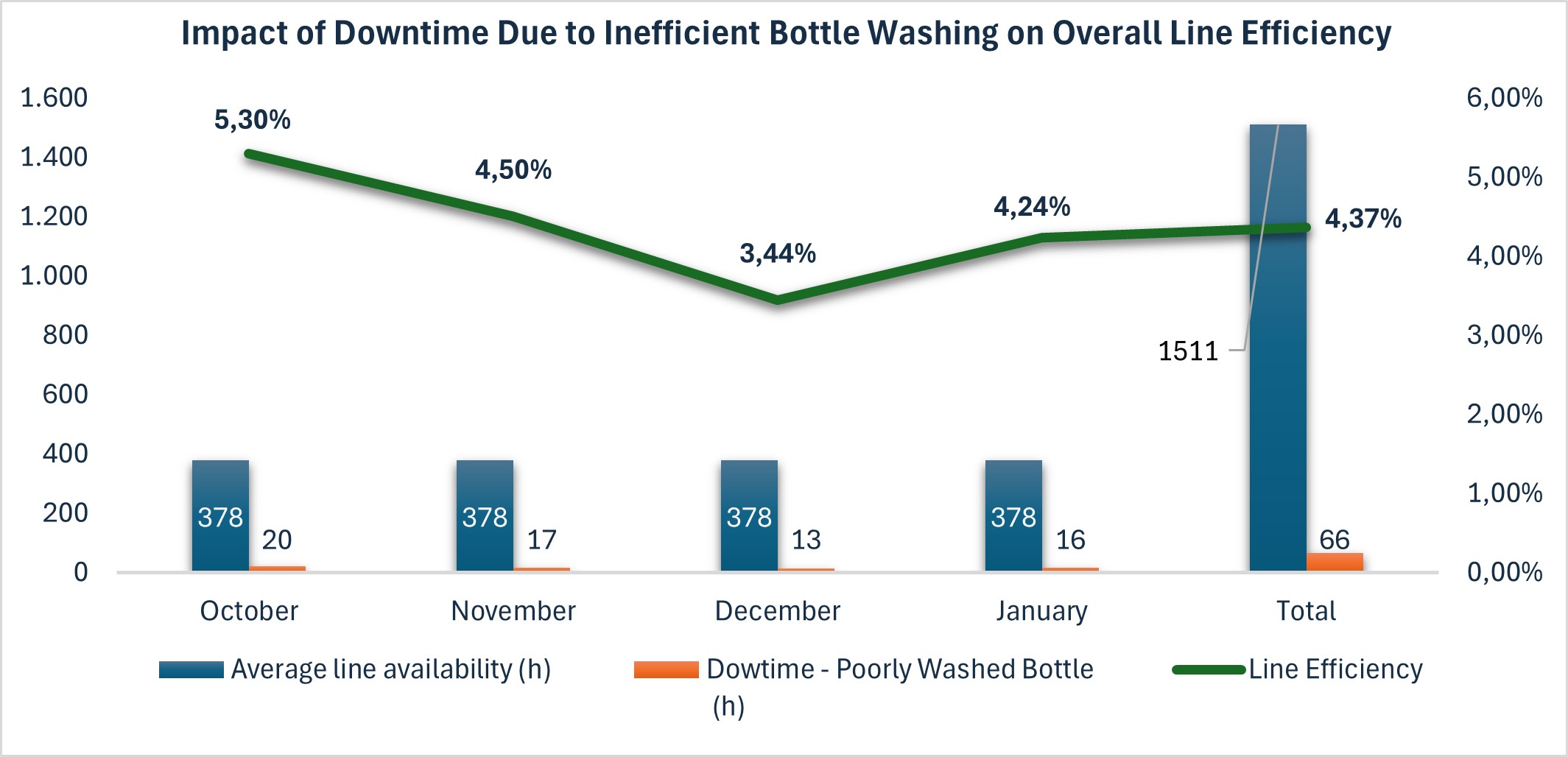

Figure 1: The impact of additives on the efficiency of bottle filling lines.

In bottle washers, washing tank levels directly influence contact time, since cleaning occurs through immersion. Low tank levels also affect label extractor performance, as the cleaning solution may not reach the extractor conveyors, preventing suspended labels from being carried out of the washer.

Figure 2: Example of poorly washed bottles due to issues with detergent solution temperature and the washing solution level in the tanks responsible for bottle cleaning.

Once washing is complete, bottles pass through final rinse tanks with potable water and proceed to electronic inspection. Bottles that do not meet cleanliness or integrity standards are returned to the process, generating new washing cycles that wear down the glass, cause micro-cracks (stress cracking), and increase costs due to re-washing.

Conclusion

The efficiency of the washing process is decisive in extending the service life of returnable glass bottles and ensuring the economic benefits of this packaging model. Strict control of variables such as chemical concentration, temperature, immersion time, and mechanical agitation is essential to avoid repeated rejections, preserve bottle integrity, and ensure consumer safety. Any imbalance in these parameters compromises the economic sustainability of returnable bottles, making continuous monitoring and proper bottle washer maintenance indispensable.