Heat exchangers are widely used in industrial systems to regulate the temperature of fluids, with numerous applications across different processes. A significant portion of the cooling equipment - designed to reduce fluid temperature – relies on cooling water. This water may come from a natural source (such as a river or sea), a cooling tower (open system), or a closed system.

An important factor in heat exchanger performance is keeping the heat transfer surfaces clean or, at the very least, minimizing the accumulation of deposits. Heat exchangers that use cooling water are typically constructed from metals that balance between cost and high thermal conductivity. Their designs indicate some important variables. Let's briefly talk about two important key aspects.

Overall Heat Transfer Coefficient

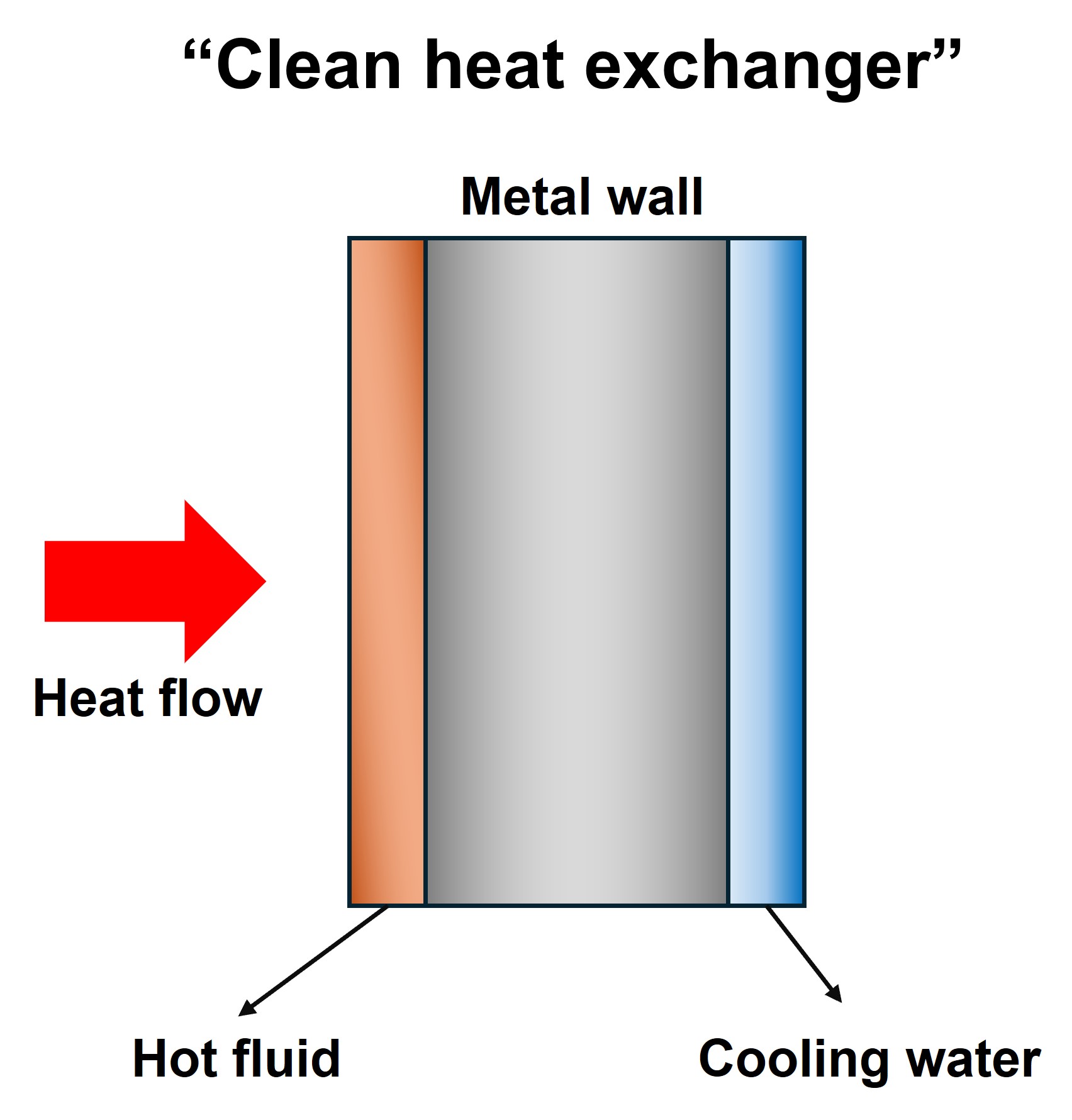

The overall heat transfer coefficient is a direct relationship with the different fluids and metals through which heat will pass. Figure 1 below illustrates a simplified scenario where a hot fluid transfers heat to water (cold fluid) through mutual contact with a metal wall. The metal wall represents the tube (of a shell-and-tube heat exchanger) or plate (of a plate heat exchanger). At the start of operation, the equipment is clean and free of any deposits. Under these conditions, the resistance to heat transfer will be the sum of the resistance of the fluids and the thickness of the metal.

Figure 1 - Heat transfer on a "clean" heat exchanger

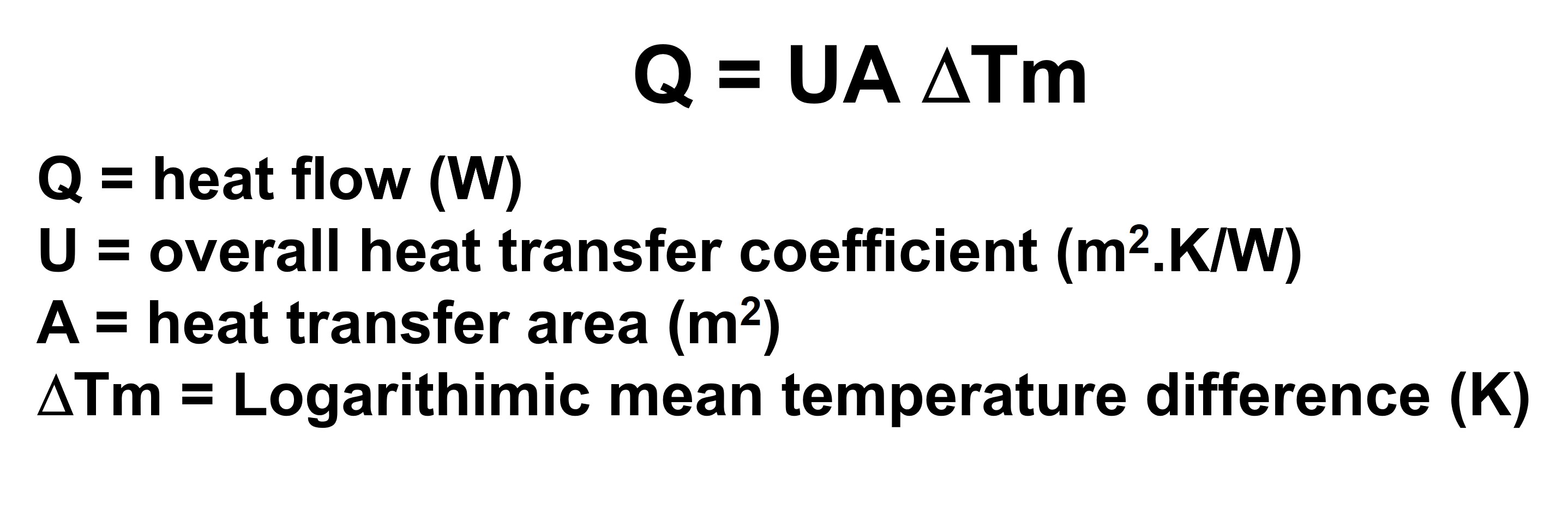

The overall heat transfer coefficient is calculated according to Equation 1 below.

Equation 1 - Heat flow.

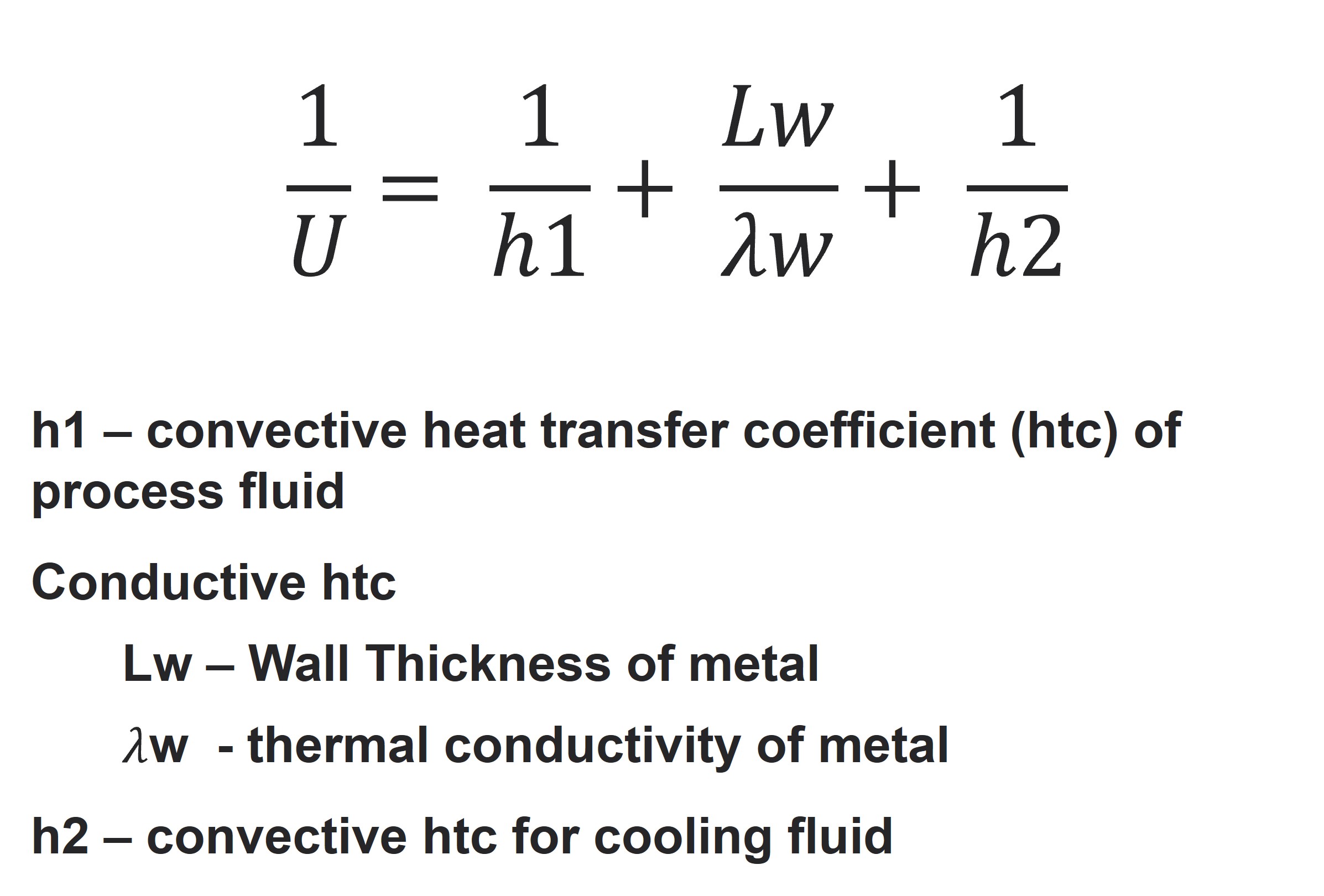

Now let's imagine that, for whatever reason, there is a deposition of unwanted material on the cooling water side. Regardless of the physicochemical nature of this material, it will exhibit lower thermal conductivity compared to the metal – metals are excellent heat conductors. Because of this extra, undesigned film of lower thermal conductivity material, this deposition inevitably represents more resistance to heat transfer. This concept is similar to electric current (in this case, heat flow) and electrical resistances (in this case, the different thicknesses of fluids and solid materials). The more layers and the thicker these layers, the greater the resistance to heat transfer. With greater resistance to heat transfer, the overall heat transfer coefficient will be lower.

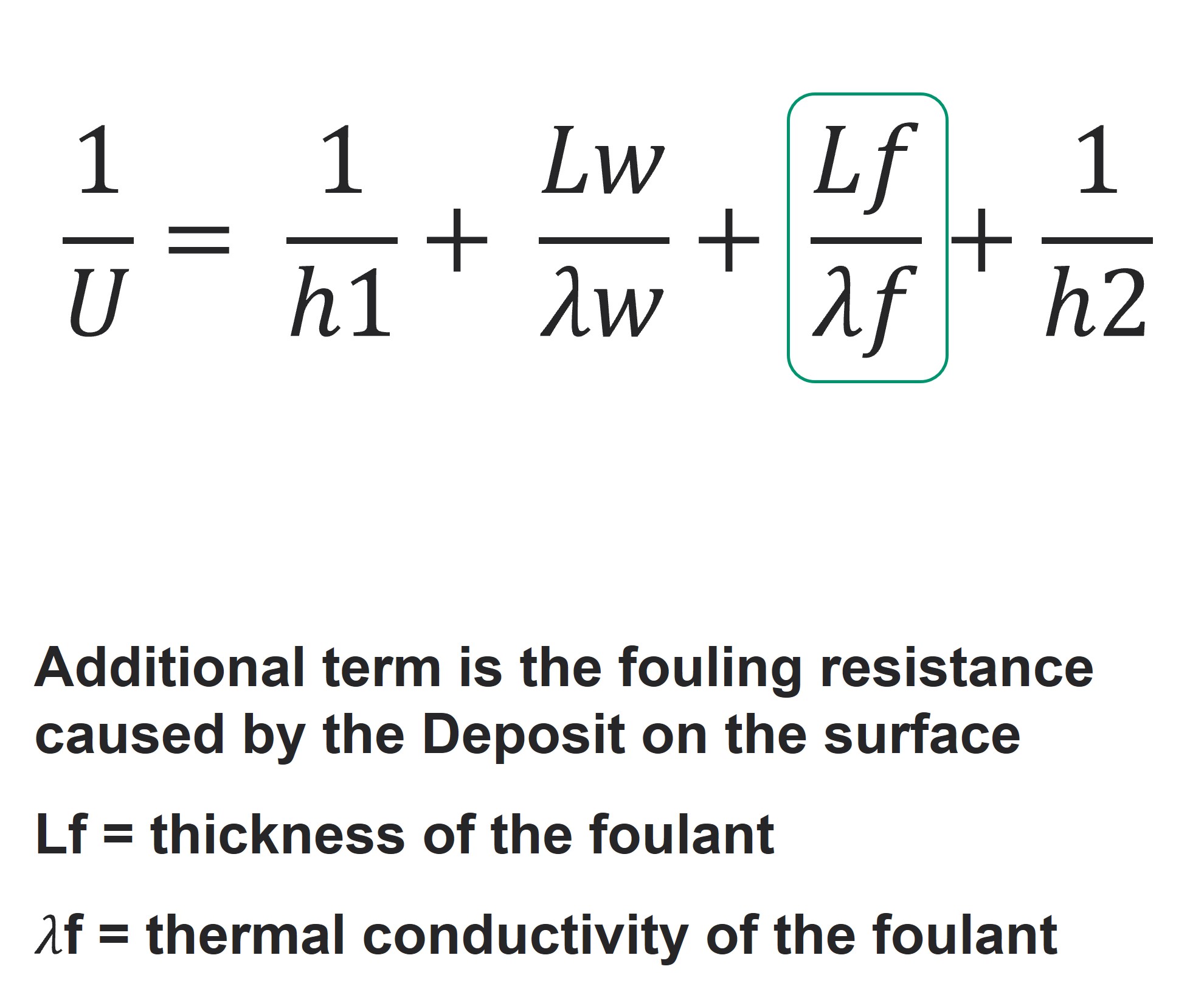

Equation 2 below provides a mathematical representation of how the overall heat transfer coefficient is a consequence of the sum of resistances to heat flow.

Equation 2 - Overall heat transfer coefficient as a consequence of all heat resistances.

Figure 2 illustrates a situation where deposition occurs on the cooling water side. This deposition reduces heat transfer, consequently reducing the overall heat transfer coefficient.

Figure 2 - Fouled heat exchanger.

In this new scenario, where deposits have formed on the surface, an additional resistance to heat transfer appears, as represented in Equation 3 below.

Equation 3 - Overall heat transfer with extra resistance calculation.

Fouling Factor

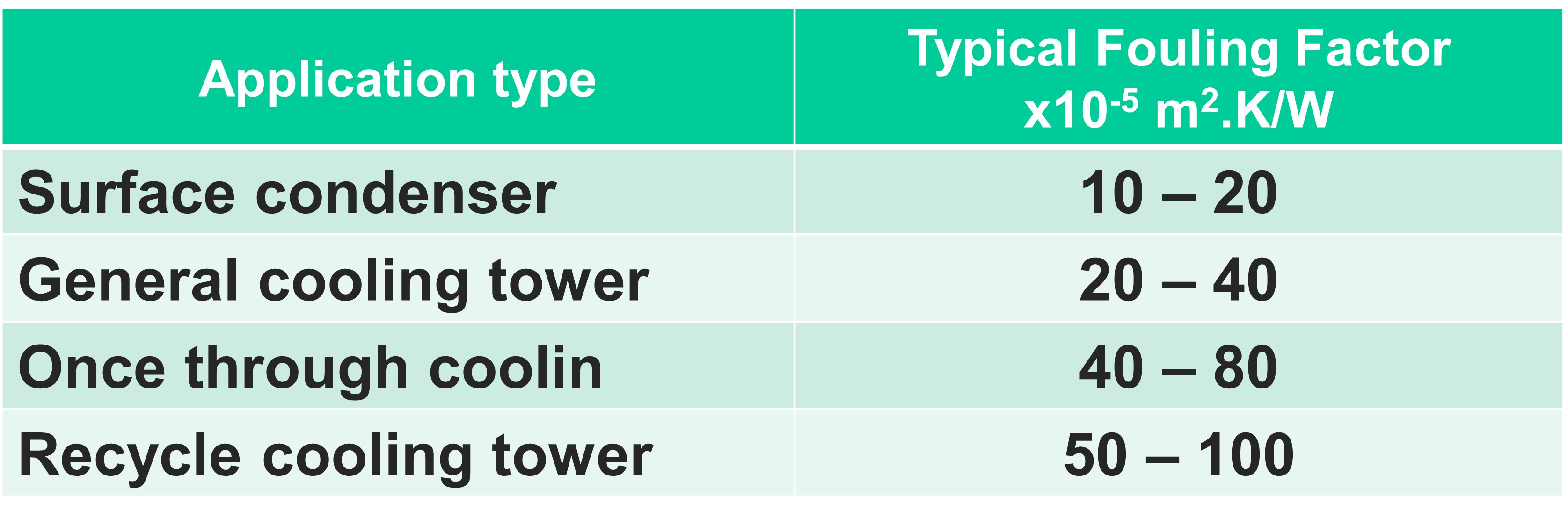

Fouling factor is mathematically represented as the inverse of the overall heat transfer coefficient. The greater the resistance to heat transfer, the lower the overall heat transfer coefficient and, consequently, the higher the fouling factor. Heat exchanger designs already anticipate a maximum acceptable amount of fouling factor so as not to significantly impair overall heat transfer. This value is usually highlighted in the manual or datasheet of each heat exchanger. Table 1 below illustrates some literature references on typical maximum fouling factor recommendations.

Table 1 - Typical fouling factors for different cooling water operations.

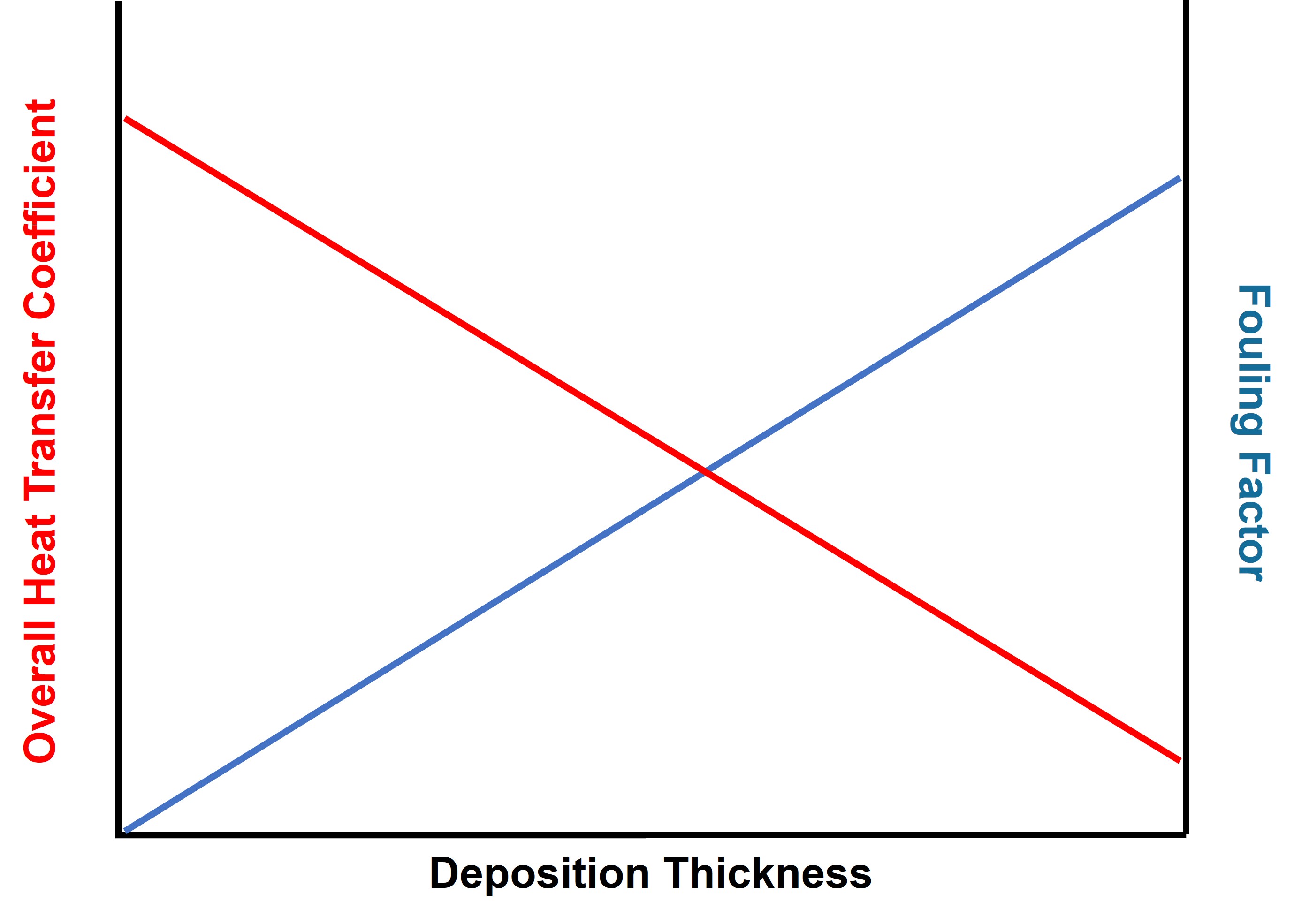

The summary of the correlation is described in Figure 3. The higher the fouling factor, the lower the overall heat transfer coefficient. Consequently, the heat removal performance of the hot fluid will be lower. This condition can lead to quality losses, production losses, increased cooling water consumption, the need for mechanical intervention in heat exchangers, among many other problems.

Figure 3 - Relationship between overall heat transfer coefficient and fouling factor.

Conclusions

Monitoring thermal performance, such as the overall heat transfer coefficient, along with other variables like velocity, heat transfer surface condition (HTSC) - HOW TO DETERMINE THE MOST CRITICAL HEAT EXCHANGER AT AN INDUSTRIAL SITE | LinkedIn) - , film temperature, and all physicochemical control parameters, is essential for ensuring proper operation and extending the service life of heat exchangers.”

Effective water treatment relies on understanding each operation’s unique characteristics and continuously optimizing every step of the process. At Solenis, we combine innovative chemistries, advanced monitoring and control systems, and expert support to help our partners overcome these challenges and operate more efficiently and sustainably.

Learn more about how our water treatment solutions can help you achieve your operational and sustainability goals: https://www.solenis.com/en/products-and-services/water-treatment/