Two game-changing technologies from Solenis are enabling geothermal power producers to effectively address wellbore scaling and, as a result, restore well performance and boost production efficiency. These technologies not only extend the useful life of production and reinjection wells but also support the broader goal of sustainable energy production.

GeoSol™ Performance Modeling Tool

The GeoSol performance modeling tool is a proprietary web-based application that allows geothermal power producers to assess the likelihood of calcite scale formation in production wells and surface equipment. By inputting brine and gas chemical analyses, the tool calculates downhole chemical composition, pH and thermodynamic saturation indices of potential mineral scales. This predictive capability enables plant personnel to identify the likeliness of calcite scaling, facilitating proactive maintenance and treatment strategies.

The tool leverages WATCH Version 2.4 software to ensure accurate modeling based on established geothermal chemistry principles. Geothermal operators can use this tool on their own or with the guidance of their Solenis field representative.

GeoSol™ Well Cleaning Program

Over time, geothermal wells can experience diminished production capacity due to the accumulation of mineral scales in production and reinjection wells, as well as in surrounding rock fissures. The GeoSol well cleaning program offers an innovative solution to restore well performance.

The GeoSol well cleaning program utilizes a customized application of cleaning chemicals to dissolve scale buildup. It utilizes advanced concepts from reservoir engineering, geology and fluid dynamics, applying low concentrations of chemicals at high pressure and flow rates. This approach allows the cleaning agents to penetrate the rock fissures effectively. Key benefits of this program include increased production or reinjection capacity, improved plant safety and increased operational efficiency.

Figure 1 - GeoSol performance modeling software.

Customer Successes

Solenis’ performance modeling tool and well-cleaning program have helped numerous customers around the globe overcome operational declines in production and reinjection capacity, as described in the following case histories.

Case History 1 – Improved Reinjection Capacity and Plant Safety

A large geothermal power plant located in the Manisa region of Turkey faced production challenges as calcium carbonate scale and other deposits significantly increased pressures within one of the plant’s reinjection wells. In addition to the risks presented by the high pressures, the deposition in the reinjection well resulted in significant energy loss for the plant and hindered the commissioning of a new production well.

Solenis analyzed the geothermal system and performed a comprehensive study of the various scale types plugging the reinjection well. The GeoSol well cleaning program was proposed to address the scale deposition in hard-to-reach capillaries within the reinjection well.

After startup of the well cleaning program, the well pressure dropped from 45 to 34 bar and reinjection capacity increased by 170 cubic meters per hour. This improvement in reinjectivity indicated a more responsive and efficient geothermal system. Notably, the plant was also able to shut down one reinjection booster pump after completing the well-cleaning program, resulting in a one-megawatt energy savings.

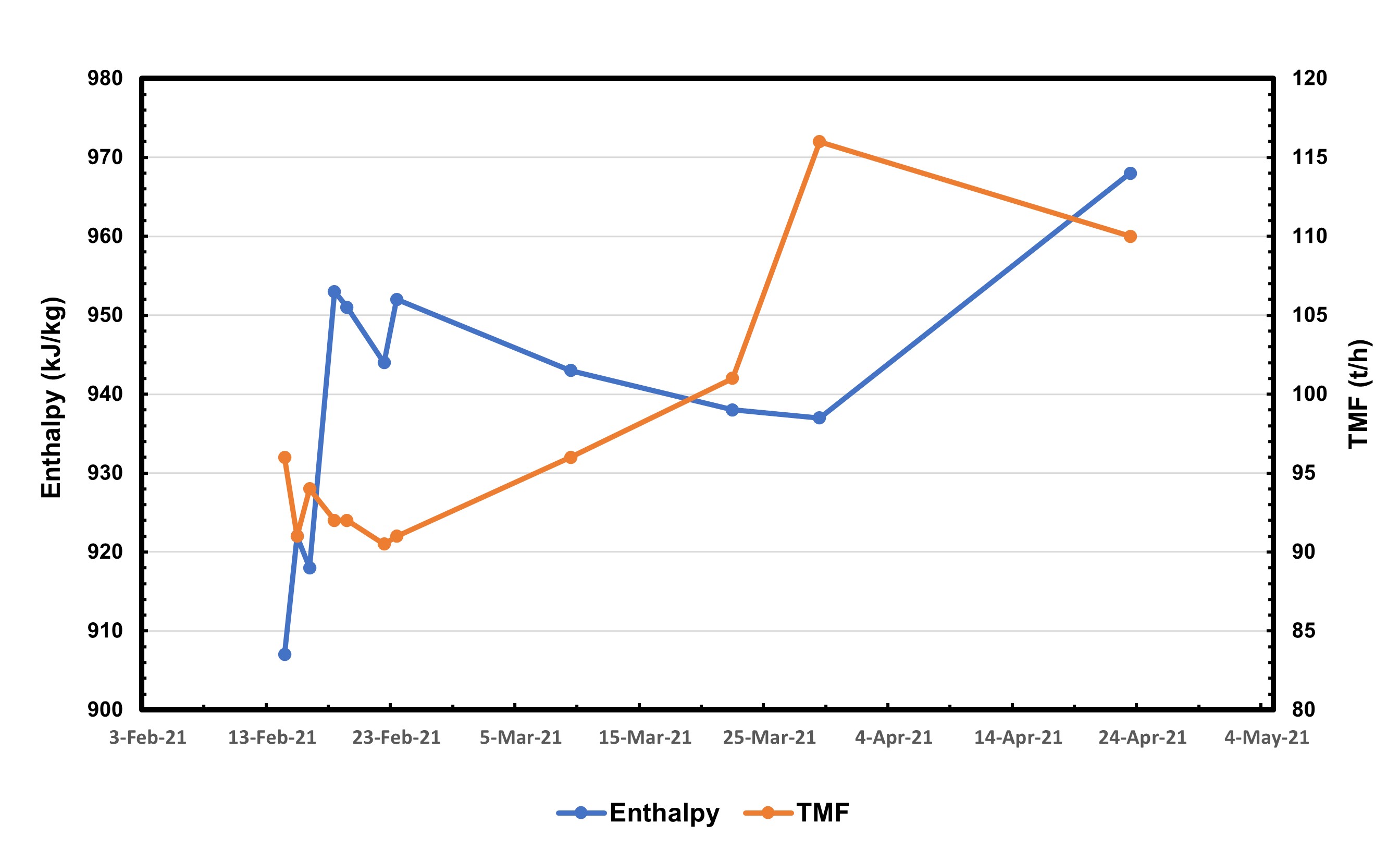

Case History 2 – Improved Well Enthalpy and Total Mass Flow

A geothermal power producer in Guatemala was having significant issues with one of its production wells. This well was shut in after it was determined that it could not sustain continuous flow to the power plant. After being shut in for a few months, the well was repurposed as a reinjection well in hopes that this would enhance the permeability of the formation. After reassessing the well, the geothermal operators thought they would be able to bring the well back online as a production well, but the well head pressure only remained consistent for three months. It was assumed that this was due to significant scaling.

Solenis was brought in to offer a solution to the scaling issue and conducted an analysis of the well. After receiving the fluid samples, the Solenis team was able to use the GeoSol performance modeling tool to gain insight into what was happening inside the well. Using the tool, Solenis was able to simulate the calcite saturation and, as a result, propose an ideal antiscalant to combat the scaling issues.

Three months after continuously feeding the antiscalant, the plant ran Go-Devil tests and there was no sign that the well diameter was reduced or obstructed by deposits. Further surveys indicated that thermal recovery is still occurring but there has been an improvement in well enthalpy and total mass flow indicating improved power production.

Figure 2 - Enthalpy and total mass flow (TMF) while under Solenis program.

To learn more about our solutions for geothermal power producers, contact a Solenis expert today.